Cyclodextrin Industry Trends and Globalization Opportunities for Chinese Companies

Cyclodextrin derivatives such as HPBCD and SBECD are increasingly important as functional excipients for pharmaceuticals, cosmetics, and advanced consumer products. This article examines market dynamics, manufacturing innovations, application areas, and the strategic advantages that Chinese suppliers bring to global value chains.

Overview: Why Cyclodextrin Matters

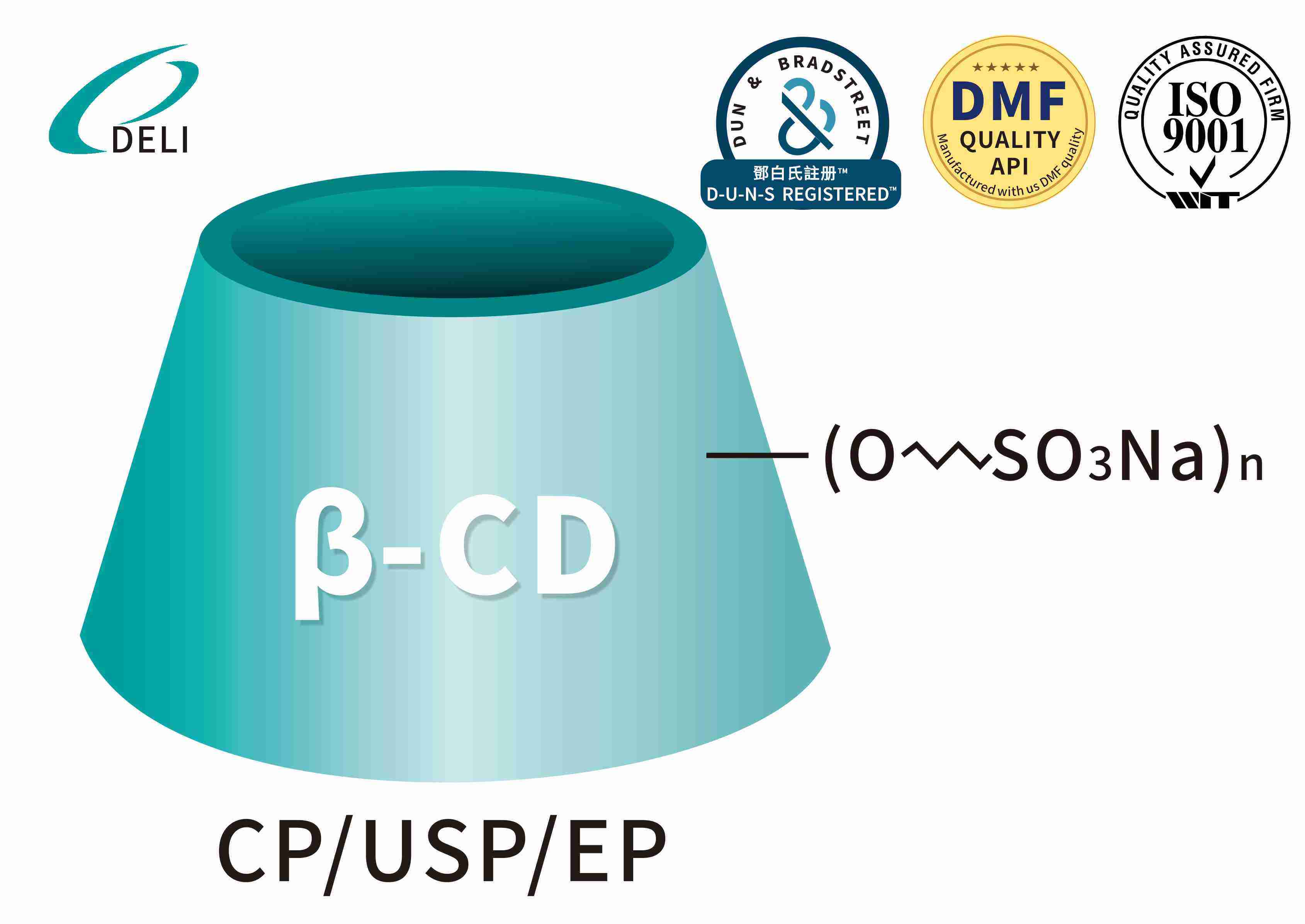

Cyclodextrins are a family of cyclic oligosaccharides characterized by a hydrophilic exterior and a hydrophobic cavity. This structural feature enables the formation of inclusion complexes with poorly soluble active ingredients, making cyclodextrin derivatives valuable pharmaceutical excipients for improving drug solubility, stability, and bioavailability. Notable derivatives include Hydroxypropyl betadex (HPBCD) and Betadex Sulfobutyl Ether sodium (SBECD), which are widely adopted in oral, topical and parenteral formulations.

Global Market Trends

The global cyclodextrin market has entered a phase of steady expansion driven by pharmaceutical innovation and growing consumer demand for functional, stable formulations. Key drivers include:

- Pharmaceutical demand: Increasing development of poorly soluble APIs and biologics that require solubility-enhancing excipients.

- Cosmetic and personal care: Use of cyclodextrin to stabilize fragrances and active ingredients, improving shelf life and consumer experience.

- Food and nutraceuticals: Flavor encapsulation and controlled release in functional foods and supplements.

- Sustainability preferences: Consumer and regulatory pressure favoring biodegradable, starch-derived excipients.

Market forecasts show multi-year growth for cyclodextrin segments, with medical-grade and injectable-grade derivatives (for example, SBECD used in parenteral drugs) commanding premium demand due to stringent quality and regulatory requirements. As drug delivery challenges continue to grow, cyclodextrin’s role as a formulation tool will expand across dosage forms.

Green Manufacturing and Process Innovation

One of the most significant shifts in the cyclodextrin industry is the move toward greener production methods. Manufacturers are adopting technologies and process designs that minimize solvent use, reduce energy consumption, and increase raw-material efficiency. Notable technical directions include:

- Enzymatic synthesis: Biocatalysis can improve selectivity and lower harsh chemical usage in derivatization steps.

- Solvent-free and mechanochemical methods: Ball-milling and solid-state reactions reduce reliance on organic solvents.

- Continuous-flow processing: Microreactors and flow chemistry enhance heat and mass transfer, enabling safer and more scalable production.

- Membrane and chromatography improvements: Advanced purification reduces waste and yields higher-purity products with smaller footprints.

Adoption of these innovations supports regulatory compliance and reduces lifecycle environmental impact—an increasingly important factor for global customers contracting excipient suppliers.

Applications: From Injectables to Cosmetics

Cyclodextrin derivatives find use across diverse sectors due to their inclusion-complex chemistry:

- Pharmaceuticals: HPBCD and SBECD are critical in oral and parenteral formulations to prevent precipitation, improve dissolution rate, and reduce local irritation. Injectable grade SBECD is often chosen for IV formulations where safety and solubility are critical.

- Cosmetics and personal care: Cyclodextrins stabilize volatile actives and fragrances, control release profiles, and can reduce skin irritation by complexing potentially irritating molecules.

- Food and nutraceuticals: Applications include flavor encapsulation, bitterness masking, and incorporation of lipophilic nutraceuticals into aqueous products.

- Veterinary products: Formulation strategies developed for human APIs often translate to animal health, expanding market opportunities.

Competitive Advantages of Chinese Suppliers

Chinese companies are increasingly prominent in the cyclodextrin value chain. Several structural advantages underpin their competitiveness:

- Scale and cost-efficiency: Large production bases and integrated supply chains support competitive pricing for bulk excipients.

- Capacity expansion: Rapid capacity growth enables timely response to large-volume procurement needs.

- Growing technical capability: R&D investments in purification, derivatization, and green processing raise product quality toward pharmacopeial standards (HPBCD, SBECD).

- Regulatory alignment: Increasing numbers of suppliers obtain pharmacopeial certificates and export documentation that facilitate market entry in regulated regions.

For global partners, Chinese suppliers can offer a combination of responsiveness, cost competitiveness, and improving compliance—making them attractive for contract development, pilot supply, and commercial sourcing when quality systems and documentation are in place.

Outlook: Next Ten Years

Over the next decade, the cyclodextrin market is expected to mature along two parallel tracks:

- High-value medical and specialty applications: Continued growth in injectable and novel delivery systems, where Hydroxypropyl betadex (HPBCD) and Betadex Sulfobutyl Ether sodium (SBECD) serve critical roles, will expand the premium segment.

- Volume markets in consumer industries: Cosmetics, nutraceuticals, and food sectors will drive large-volume demand for cost-effective, sustainably produced cyclodextrins.

Key success factors for suppliers will include investment in green manufacturing, rigorous quality systems (including COA and pharmacopeial compliance), and global logistics capabilities. Strategic partnerships with formulators and contract development organizations (CDMOs) will accelerate adoption of cyclodextrin-enabled formulations.

Company Introduction

Xi'an Deli Biochemical Industry Co.,Ltd. is a China-based enterprise specializing in cyclodextrin derivatives including Hydroxypropyl betadex (HPBCD) and Betadex Sulfobutyl Ether sodium (SBECD). With an integrated production and quality-control platform, Xi'an DELI focuses on delivering high-purity excipients for pharmaceutical, cosmetic, nutraceutical, and veterinary applications. The company emphasizes green process development, technical support for formulation teams, and documentation to meet global regulatory needs.

For inquiries about cyclodextrin products, technical data, or sample evaluation, contact us through the website or designated regional representatives.