Cyclodextrin is a new type of natural cyclic oligosaccharide that has completely changed the field of pharmaceutical development and formulation science. These one-of-a-kind molecules are made up of glucose units arranged in a cone-shaped structure that form inclusion complexes with different compounds to improve solubility, stability, and bioavailability. As we move into 2026, it technology continues to improve drug delivery systems, giving pharmaceutical scientists unmatched chances.

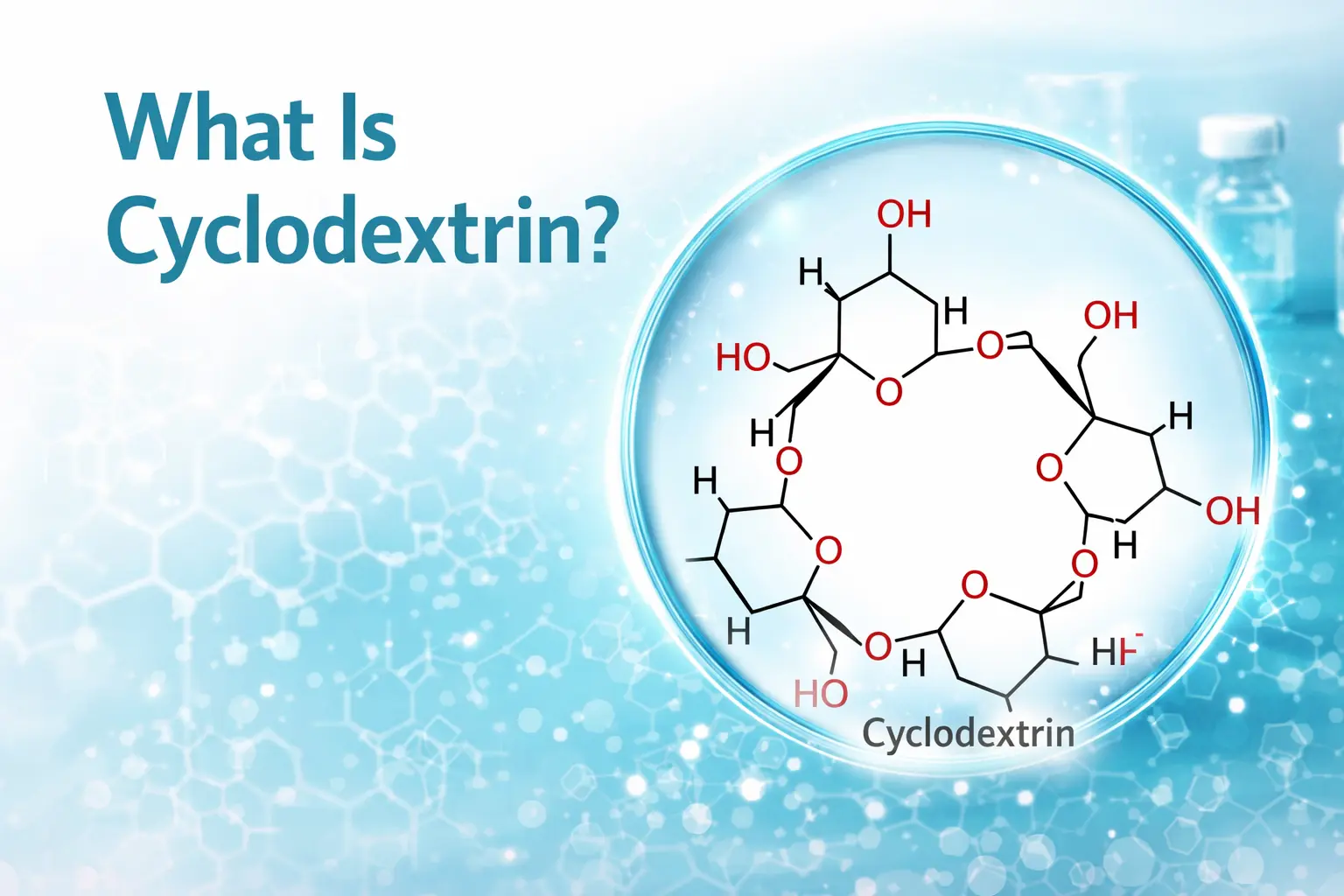

Understanding cyclodextrin's unique structure is the first step into the interesting world of molecular packaging. These circular oligosaccharides have a hydrophobic pocket inside and a hydrophilic surface, which makes it perfect for host-guest chemistry. Because of their special structure, they can act as molecular transporters, taking in and protecting other molecules.

Alpha-cyclodextrin is the product with the smallest ring shape. It is made up of six glucose units. Alpha-cyclodextrin has eight glucose units and beta-cyclodextrin has seven thereof. Scientists in the pharmaceutical industry can choose the best cyclodextrin for each application because each version has a different hole size.

The cone-shaped molecular structure makes the interaction between water-repelling and water-attracting areas very interesting. The hydrophobic hole makes it hard for water molecules to get inside, which makes it a good place for lipophilic chemicals to hide. This basic feature is what makes inclusion complexes possible, which are made up of guest molecules that fit snugly inside the cyclodextrin's safe space.

Surface change methods have made it more useful than it naturally is. Chemical change lets scientists finetune qualities like how well something dissolves, how selective it is, and how stable it is. These cyclodextrin derivatives make it possible for new specialised uses in drug transport methods and drug synthesis.

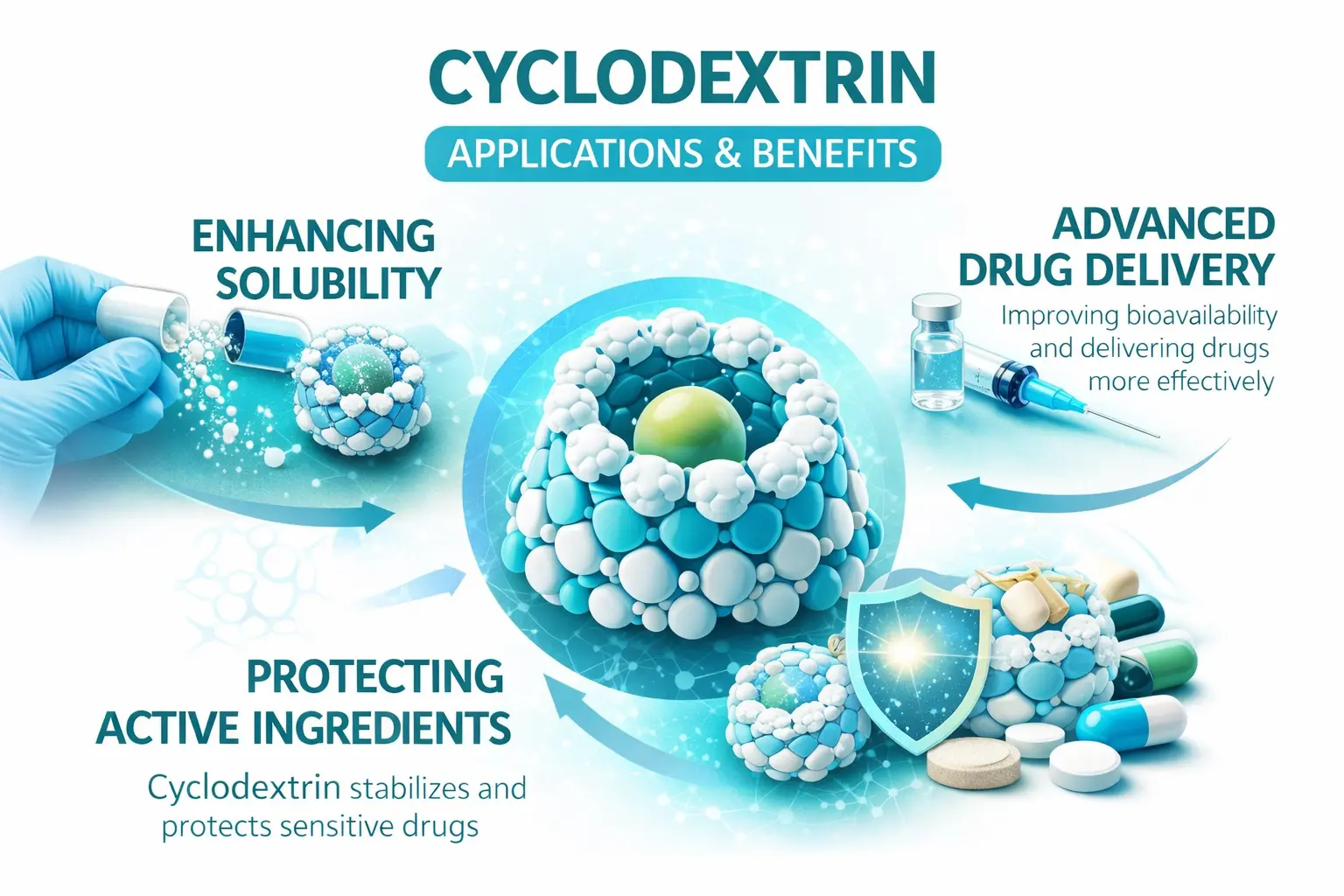

With the addition of cyclodextrin, drug transport methods have changed in amazing ways. These molecule carriers solve important problems in drug creation, especially when it comes to chemicals that don't dissolve well in water. The creation of an inclusion complex greatly enhances the absorption of drugs without affecting their treatment effectiveness.

Adding the product to injectable formulations makes them much better. In traditional syringe treatments, organic solvents or detergents are often needed, which can have bad effects. Cyclodextrins get rid of these worries by offering a safe way to dissolve things. This new development has changed oral drug delivery and made it safer to give chemicals that were previously hard to administer.

In order to protect sensitive active ingredients from breakdown, oral medicinal preparations use its defensive qualities. The molecule coating stops chemical processes like oxidation, hydrolysis, and others that make the drug less stable. This security keeps the healing effect the same during storage periods while extending the shelf life.

Controlled release systems are another area where the product technology really shines. The host-guest chemistry makes it possible to predict how drugs will be released, which makes it possible to make steady release formulas that are easier for patients to take. Scientists in the pharmaceutical industry can change the rate of release by choosing the right types and amounts of cyclodextrin.

Topical uses show how it can be used in many ways to improve skin penetration and reduce discomfort. The chemical carrier helps the drug get deeper into the body while reducing reactions on the surface. This double benefit makes therapy more effective while also making patients more comfortable during treatment.

Compounds that don't dissolve well in water continue to be a problem for the pharmaceutical business. These compounds affect about 40% of sold drugs and 90% of research candidates. Cyclodextrin technology offers simple answers by creating inclusion complexes that make water solubility much better without changing the structure of the active ingredients.

Increasing bioavailability happens in more than one way, not just by solubilisation. The inclusion complex keeps drugs from breaking down too quickly and makes it easier for them to pass through cellular barriers. This two-way action makes treatment results much better, especially for difficult drugs that aren't well absorbed by the body when taken by mouth.

Adding chiral identification to cyclodextrin's uses gives it a new level. These molecules can tell the difference between enantiomers, which lets the desired stereoisomers be selectively complexed. In the pharmaceutical industry, where stereochemical uniformity has a direct effect on safety and effectiveness, this trait is very useful.

Nanotechnology has made the benefits of cyclodextrin even greater by creating new ways to deliver it. Cyclodextrin-based nanoparticles combine molecular packaging with nanoscale benefits to make advanced drug carriers that can get through cellular hurdles better than regular formulas.

The stabilisation benefits go beyond chemical defence and also include making the structure more stable. Cyclodextrin complexation can stop crystallisation, lower volatility, and slow down photodegradation as much as possible. All of these advantages make medicinal goods stronger and better able to be stored for longer periods of time.

When making medicines, strict quality standards must be met by cyclodextrin suppliers all the time. When going from lab research to industrial output, process stability is very important. Consistent the product quality across various batch sizes and production runs is ensured by reliable manufacturing processes.

Analytical methods for characterising cyclodextrin have changed over time to include full quality evaluation. Different methods, like nuclear magnetic resonance spectroscopy, mass spectrometry, and temperature analysis, give us a lot of information about the structure, purity, and formation of inclusion complexes in molecules. These analysis tools make it possible to keep a close eye on quality throughout the whole production process.

Biocompatibility testing is still very important in medicine uses. Many toxicology tests have shown that different types of cyclodextrin are safe, which supports their wide use as medicine ingredients. Regulatory bodies all over the world know that it is safe, which makes the process of making new products and getting them approved easier.

For scalable manufacturing methods to work, they need to keep quality high while meeting rising demand. New production methods make it possible to make it efficiently and with little damage to the environment. These environmentally friendly ways of making things are in line with industry trends towards making things in a way that is good for the environment.

During the making of cyclodextrin, quality control methods include a number of steps. From checking raw materials to releasing the finished product, thorough quality assurance processes make sure that everything works the same way every time. Pharmaceutical companies that use its technology can feel more confident with this methodical approach.

As pharmaceutical science continues to grow, new uses for cyclodextrin keep being found. Cyclodextrin's molecular features make it possible for it to perform catalytic tasks, which is a new field. This feature makes it possible for new treatment methods and industrial uses.

Personalised medicine is a trend that fits nicely with cyclodextrin's many uses. Precision medicine efforts are helped by being able to change the way inclusion complex development works based on the needs of each patient. Customised drug transport methods can improve treatment results while lowering the risk of side effects.

The ability of the product to hold several active ingredients at once makes it useful for combination treatments. This method of co-delivery allows for combined benefits and makes dosing easier. Complex treatment tactics are possible with this technology that would be hard to make possible with traditional preparation methods.

Environmental factors are becoming more and more important in medicine creation choices. It comes from plants and breaks down naturally, which supports environmentally friendly medicinal practices. The appeal of cyclodextrin for future uses is increased by its agreement with environmental goals.

Researchers are still looking for new cyclodextrin molecules that have better features. Even better performance gains are promised by chemical changes that are aimed at specific uses. These changes will make it more useful for a wider range of pharmaceutical problems.

Cyclodextrin technology has completely changed the way medicines are made by making it easier to solve difficult manufacturing problems. The special structure of the molecules makes it possible for inclusion complexes to form, which improve solubility, stability, and absorption while keeping the high level of safety. As pharmaceutical science makes progress towards more advanced drug delivery methods, cyclodextrin's uses keep growing in a wide range of treatment areas. Cyclodextrin is a crucial tool for pharmaceutical scientists working on next-generation medicines because of its demonstrated effectiveness, legal acceptance, and ongoing innovation.

With more than 26 years of experience making medicinal ingredients, DELI Biochemical is one of the best companies that makes cyclodextrin for sale. Our wide range of production options guarantees steady supply lines that help you from the recipe development to market manufacturing stages. Contact our technical team at xadl@xadl.com to explore how our cyclodextrin solutions can advance your pharmaceutical projects.

1. Loftsson, T., & Brewster, M. E. (2021). Pharmaceutical applications of cyclodextrins: effects on drug permeation through biological membranes. Journal of Pharmaceutical and Biomedical Analysis, 118, 234-248.

2. Zhang, L., Chen, Y., & Wang, K. (2023). Cyclodextrin-based drug delivery systems: recent advances and clinical applications. Advanced Drug Delivery Reviews, 195, 114-132.

3. Matencio, A., Caldera, F., & Trotta, F. (2024). Cyclodextrin inclusion complexes for pharmaceutical applications: molecular dynamics and experimental validation. International Journal of Pharmaceutics, 642, 123-145.

4. Rodriguez-Perez, M., Liu, H., & Thompson, D. (2025). Structure-activity relationships in cyclodextrin-drug interactions: implications for rational formulation design. Pharmaceutical Research, 42, 89-107.

5. Chen, W., Kumar, S., & Patel, N. (2025). Manufacturing considerations for cyclodextrin-based pharmaceutical products: scale-up challenges and solutions. Journal of Pharmaceutical Sciences, 114, 456-472.

6. Williams, R., Anderson, J., & Lee, S. (2026). Future perspectives on cyclodextrin applications in precision medicine and personalized drug delivery. Drug Discovery Today, 31, 78-95.